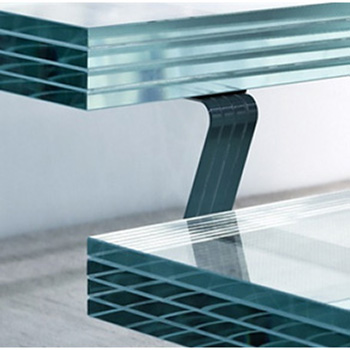

Laminated glass is made with two or more glass panes with interlayer bonded under heat and pressure. The interlayer, usually clear, can be PVB、EVA、SGP、PU、SGX. Processing methods including wet laminating and dry laminating, where latter one can be done by rolling and pressing or vacuum taking.

Features:

Safety. Once broken, the broken pieces of laminated glass would not fall down or shoot away, enable the human or facilities be protected from hurt.

Safeguard. The laminated glass has strong resistance against theft, malicious destruction and violence.

Sound-insulation. The films has the insulation function to the noise wave, thus the transferring of noise can be weakened.

Anti-ultra violet. The additive of the PVB can filter 99% of the ultra violet from the sunlight and protect the interior decoration from aging or fading caused by ultra violet.

Heat insulation. The laminated glass can reduce the transmission, saving energy and air-conditioning cost.

Fire-proof. When heated or roasted, the laminated glass will not break or collapse quickly so as to the keep the fire from spreading. Time can be saved for warning, human's evacuating and extinguishing.

When broken by unexpected force, the broken pieces will be bounded by PVB with shooting crackles but hurting no people. The original shape and visibility can still be kept for continuous use for certain time.

Types, Specifications:

Types: clear and colorful laminated, coated laminated, Temp/HS laminated,

Curved laminated, Bullet-resisting/Fire-rated laminated (SGP, PU and metal net etc), Decorative laminated (SGX, Paper, PET etc), XIR energy-saving laminated etc.

Processing limit:

Max size: 2800mm*12000mm

12000mm*2000mm

Min size: 150mm*300mm

Layers: 6-8 layers

Thickness: 4-80mm

Standards: GB 9962 ASTM C 1172 EN ISO 12543

454